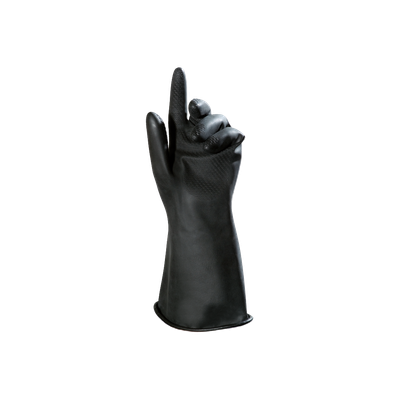

Alto 415

Fine touch for light chemical protection

-

CAT. 3

0334

0334

-

1011X

1011X

-

Type B

KMT

KMT

-

-

Specific advantages

Comfort

Comfort

- Tactile sensitivity, due to the gloves reduced thickness

- Added comfort and absorption of perspiration, due to the cotton flock-lining

Productivity

Productivity

- Good grip, due to the non-slip embossing

Guaranteed quality

Guaranteed quality

- Silicone free to prevent traces, defects on metal sheet and glass prior to painting

Care for the environment

Care for the environment

- Optimised individual packaging to limit plastic waste

- Recycled material in the packaging: 30 %

Applications

Automotive/mechanical industry

- Spray-painting

Aeronautics industry

- Work with composite materials (resins)

Other industries

- Industrial cleaning, maintenance

Product detail

| Material | Polychloroprene and natural latex |

|---|---|

| Colour | black |

| Interior finish | Flocked |

| Exterior finish | Embossed texture |

| Length (cm) | 32 |

| Thickness (mm) | 0.6 |

| Size | 6 7 8 9 10 11 |

| Packaging | 1 pair/bag 10 pairs/bag 100 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Methanol 99% | 67-56-1 | 48 | 2 | EN 374-3:2003 | NT |

|

| Nitric acid 65% | 7697-37-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 96% | 7664-93-9 | 153 | 4 | EN 374-3:2003 | NT |

|

*not normalized result

More gloves

New

New

Ultranitril 358

Designed with an embedded optimal grip to safely handle tasks in dry & greasy environments

Telsol 351

Comfort, flexibility and mechanical protection with low risk of chemical hazards