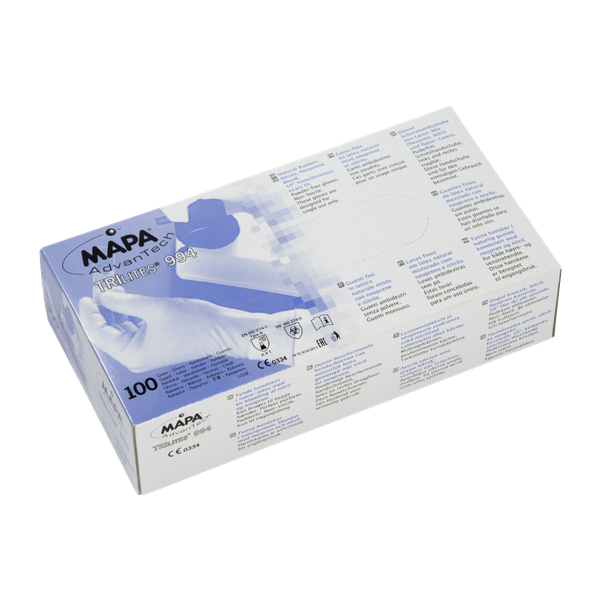

Trilites 994

Tripolymer formula for protection against chemical splashes

-

CAT. 3

0334

0334

-

Type B

KPT

KPT

-

Specific advantages

Comfort

Comfort

- Optimal thickness delivering maximum tactility with superior durability.

Durability

Durability

- Unique triple polymer blend for enhanced comfort and resistance.

Skin protection

Skin protection

- Protection against chemical splashes.

Guaranteed quality

Guaranteed quality

- Silicone free to prevent traces, defects on metal sheet and glass prior to painting

Additional benefits

Additional benefits

- User traceability on inner boxes and cartons.

Applications

Laboratory

- Manufacturing of medicines

- Pharmaceutical preparation

Product detail

| Material | Natural latex, polychloroprene and nitrile |

|---|---|

| Colour | mauve |

| Interior finish | Chlorinated |

| Exterior finish | Pebbled |

| Length (cm) | 25 |

| Thickness (mm) | 0.15 |

| Size | 6 7 8 9 |

| Packaging | 100 gloves/box 1000 gloves/carton |

| AQL Liquidproofness | 1.5 |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | 4 | 0 | ASTM F1383 | NT |

|

| Acetone 99% | 67-64-1 | <1 | 0 | EN 374-3:2003 | NT |

|

| Ammonium hydroxide solution 29% | 1336-21-6 | 10 | 0 | ASTM F1383 | NT |

|

| Benzene 99% | 71-43-2 | 1 | 0 | ASTM F739 | 1 |

|

| Bromobenzene 99% | 108-86-1 | 1 | 0 | EN 374-3:2003 | NT |

|

| Formaldehyde 37% | 50-00-0 | >240 | 5 | EN 16523-1:2015 | NT |

|

| Hydrochloric acid 35% | 7647-01-0 | 11 | 1 | EN 16523-1:2015 | NT |

|

| Hydrochloric acid 37% | 7647-01-0 | >110 | 3 | ASTM F1383 | NT |

|

| Hydrofluoric Acid 49% | 7664-39-3 | 27 | 1 | ASTM F739 | NT |

|

| Hydrogen peroxide 30% | 7722-84-1 | >60 | 3 | EN 16523-1:2015 | NT |

|

| Hydrotreated Light Naphthenic Distillate mixture | 64742-53-6 | 13 | 1 | ASTM F739 | 1 |

|

| Kerosene mixture | 8008-20-6 | 4 | 0 | ASTM F739 | 1 |

|

| Methanol 99% | 67-56-1 | <10 | 0 | EN 374-3:2003 | NT |

|

| n-Butanol 99% | 71-36-3 | 2 | 0 | EN 374-3:2003 | NT |

|

| N-Vinyl-2-Pyrrolidinone 99% | 88-12-0 | 8 | 0 | ASTM F1383 | NT |

|

| Naphtha VM&P mixture | 8032-32-4 | 0 | 0 | ASTM F739 | 1 |

|

| Nitric acid 68% | 7697-37-2 | 14 | 1 | EN 374-3:2003 | NT |

|

| Phenol 85% | 108-95-2 | 7 | 0 | ASTM F739 | 3 |

|

| Phosphoric acid 85% | 7664-38-2 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 96% | 7664-93-9 | 6 | 0 | EN 16523-1:2015 | NT |

|

| Unleaded gasoline mixture | 8006-61-9 | 1 | 0 | ASTM F739 | 1 |

|

*not normalized result